Our Team

Emily Haykoupian

Emily Haykoupian is a Materials Engineering major minoring in Child Development. She aspires to teach engineering at a community college and was ecstatic to get a sneak peek into her dream career with this project.

Kathryn Meany

Kathryn Meany is a third-year Materials Engineering major. She is interested in project-based learning and was excited to be working on a project that will leave an impact on many classes of materials students.

Acknowledgements

We would like to thank our project advisors, Dr. Kivy, and Dr. Johnson-Glauch, and College of Engineering for their support and guidance. We also want to thank the Sprague Family Foundation for sponsoring our project.

Learn-by-Doing Labs for the Materials Engineering Department's Freshman Level Courses

Motivation

The motivation behind this project was to design learn-by-doing introductory labs for Materials Engineering (MATE) students that can be used for several years. We wanted labs that broadened students’ general knowledge of materials and that will prepare them for the MATE curriculum. Students that participate in hands-on introductory engineering courses perform better in subsequent engineering courses.[1] Additionally, we aimed to introduce first year students to the possibilities of materials engineering in the real world. We created two labs for the freshmen-level materials courses.

Composites Lab

This lab was designed with the goal to introduce freshmen to composite materials and how different composite types and compostions can alter material properties. We are engaging students with hands-on work and experience with testing equipment.

Learning Objectives

Define what a composite material is.

Identify the three different types of composites explored in this lab.

Create the strongest CMC brick with plaster under the constraints set in the problem statements.

Defend design choices for brick in recommendation memo.

Designing and Creating a Composite

Students will design and hand-make composite

bricks with a plaster matrix (ceramic-matrix composite) and chosen supplies for

reinforcements.

Students will then bake their composite samples to dry them before testing.

Hands-On Testing

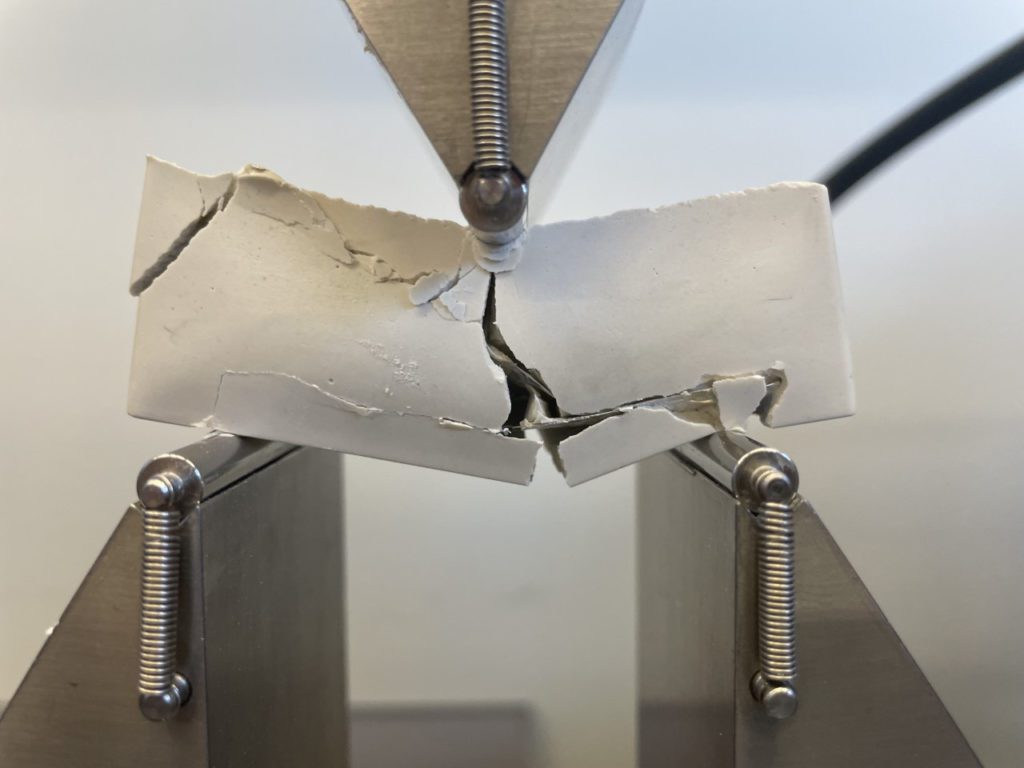

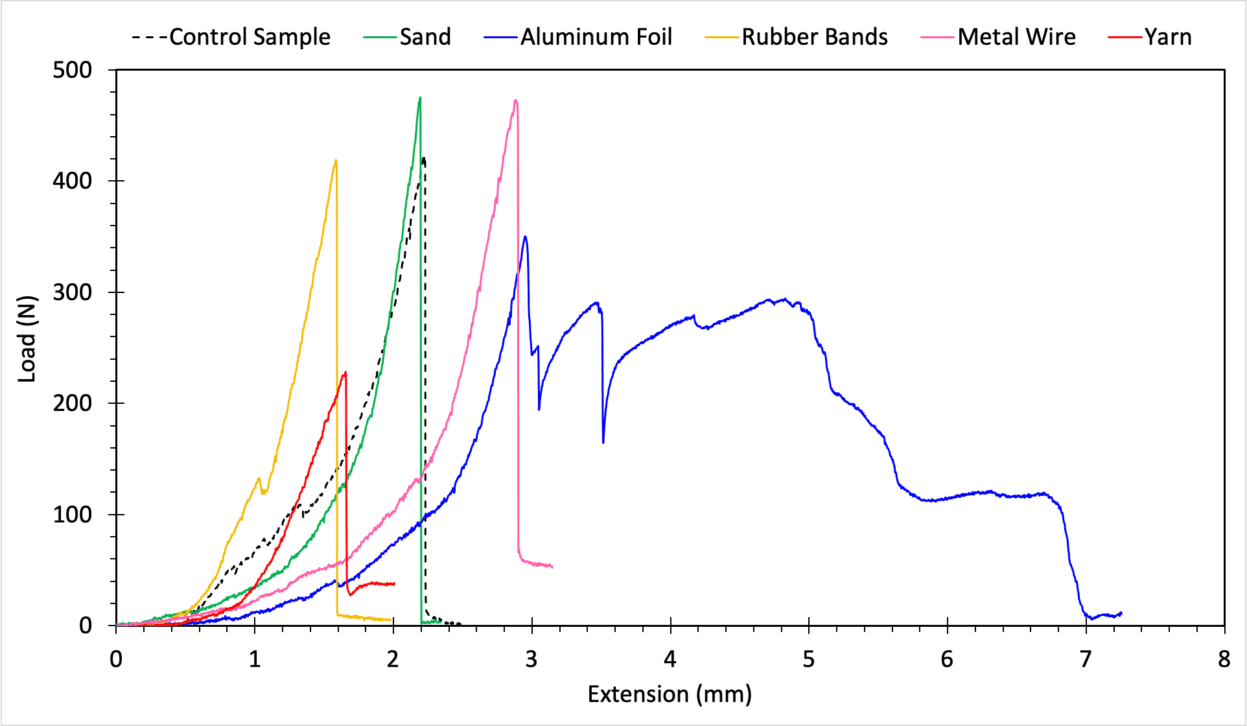

Students will utilize a three- point bend test [2] to collect data for maximum load and extension of their samples.

This is an example of what a broken composite sample will look like after testing.

Deliverables

Students will use data to write a recommendation report in technical memo format based on the success of their designs. Data will be presented in a generated Load vs. Extension curve.

Materials Selection and Design Lab

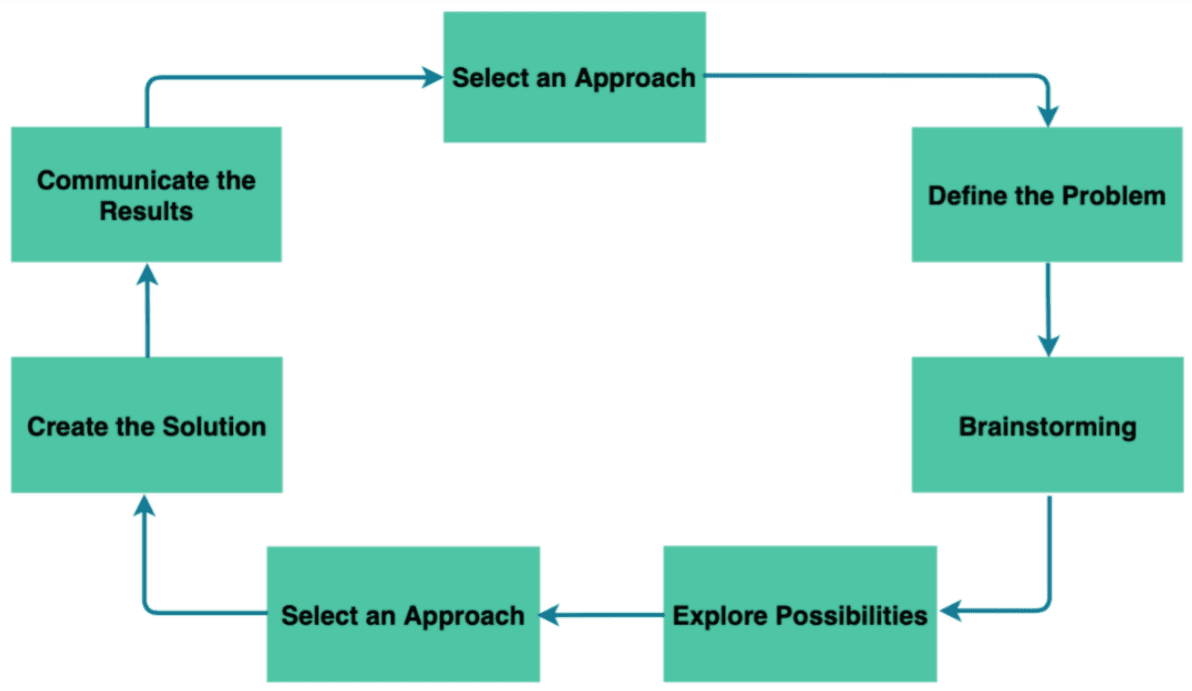

This lab provides an insight into real-world applications of materials engineering for freshmen students as well as an introduction to software like Granta EduPack that they will be using throughout their education. This lab will teach students problem solving by incorporating the principles of materials selection into the engineering design process. Students will use both to propose and defend solutions to real-world problems.

Learning Objectives

Analyze different material properties for their application.

Utilize the design process to design a material from start to finish.

Use Granta EduPack to find materials, material properties, and processing techniques.

Distinguish what processing properties can be used for different materials.

Defend their knowledge and design choices.

Considering Material Properties

Students select properties important for an engineering application that they choose.

Practicing Materials and Process Selection

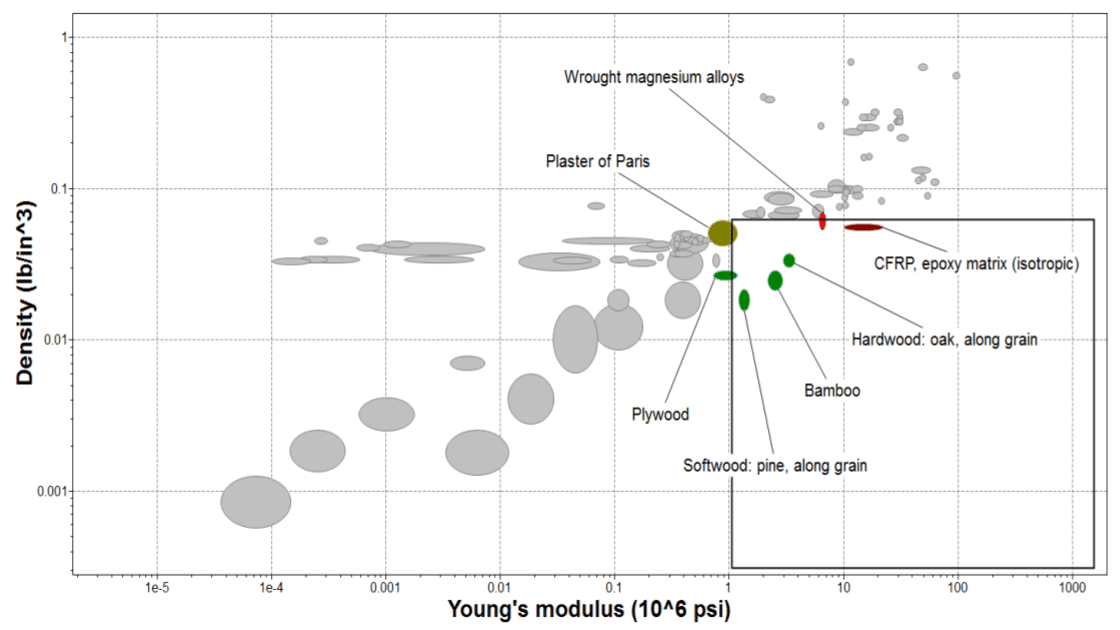

Students will utilize Granta EduPack [3] to plot their decided material properties against each other and use these graphs to select the best material for their application. Then, they will look into processing techniques using Granta EduPack and the internet.

Deliverables

Each student group will be creating a technical poster to showcase their selected material in relation to the materials engineering tetrahedron.

References

[1] H. Nguyen, L. Wu, C. Fischer, G. Washington, and M. Warschauer, “Increasing success in college: Examining the impact of a project‐based introductory engineering course,” Journal of Engineering Education, vol. 109, no. 3, pp. 384–401, Jan. 2020.

[2] ASTM D790-17, Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials, ASTM International, West Conshohocken, PA, 2017.

[3] Ansys Granta EduPack software, ANSYS, Inc., Cambridge, UK, 2020.