MEET THE TEAM

These are the students who worked on the Beneficiation of Raw Gypsum Ore SURP project over the course of the summer. A brief introduction of each student is presented.

Gunnar Hollingshaus

Gunnar Hollingshaus is a third-year student studying materials engineering at California Polytechnic University, San Luis Obispo. Gunnar primarily worked on the filtering, sieving, and chemical beneficiation methods for the SURP project Beneficiation of Raw Gypsum Ore. In the future, Gunnar hopes to do more research in the field of materials engineering. Some of his areas of academic interest include materials characterization, metallurgy, and corrosion. Gunnar is considering pursuing a doctorate degree in materials science or nuclear engineering with a specialization in nuclear materials. He aspires to work and do research at a national laboratory.

Kristine Kodama

Kristine Kodama is a second-year materials engineering student attending California Polytechnic State University, San Luis Obispo. She has worked on projects studying the relationship between particulate matter in the atmosphere and the percentage of biodiesel in a petroleum mixture and examining the effects on chitosan’s molecular structure when adding different percentages of plasticizers to chitosan. In her SURP project, she focused predominantly on the centrifugation method of beneficiation. She is currently continuing research that started with SURP and is working a part-time job digitizing tide wave measurements. Kristine is also an active member of the Formula SAE team on campus. She aspires to work in the automotive or aerospace industries in the future.

Acknowledgements

We would like to acknowledge Dr. Jean Lee from Cal Poly, Brian Maxted from H.M. Holloway, Bernard Brown from H.M. Holloway, and the Cal Poly SURP coordinators. The dedication and coordination of all these amazing people allowed for a successful learning experience. We are grateful to the Cal Poly College of Engineering for proceeding with the SURP program despite COVID-19 complications.

OUR PROJECT

Abstract

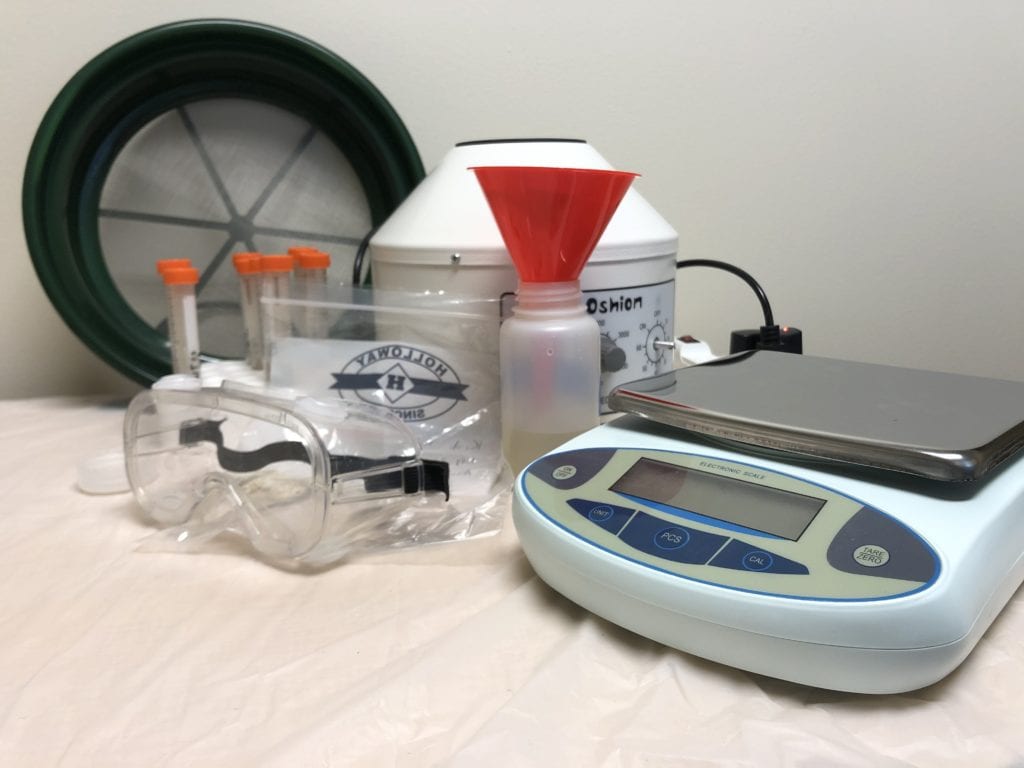

The objective of this project is to design and test proof-of-concept beneficiation processes for H.M. Holloway, a producer of agricultural soil amendments. Beneficiation is the separation of ore constituents into economically valuable components. For raw gypsum ore, beneficiation consists of separating the ore into its three main constituents: gypsum (calcium sulfate dihydrate), clay (calcium bentonite), and quartz (silicon dioxide). Each constituent holds potential economic value as soil amendment to help produce healthier plants and increase crop yield. H.M. Holloway will be considering the results of this project to determine whether it should bring water and utilities to its raw gypsum ore mine location.

Centrifugation

The centrifuge method of beneficiation tested two overarching categories: dry and wet ore samples. The dry samples provided negligible separation results with respect to variables of time and speed of centrifugation and ore particle size. However, the wet samples resulted in more visible separation, with the water ratio variable exhibiting the most stark separation out of all the variables tested.

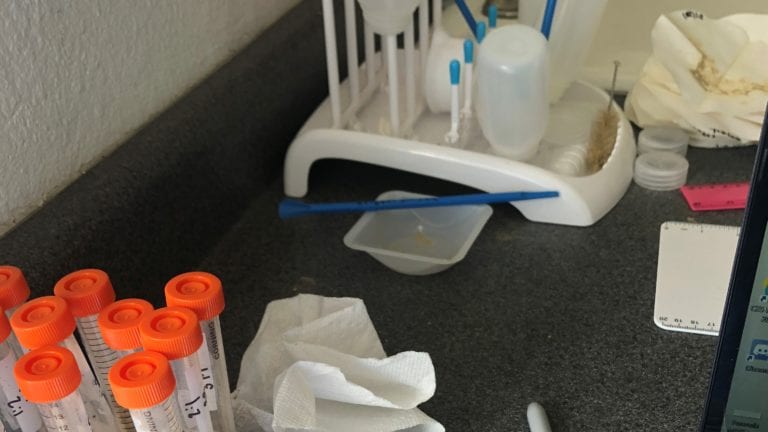

Effects of Water Ratio

This experiment involved the comparison of a 1:2 (by mass) water : ore ratio, a 1:1 ratio, and a 2:1 ratio after being centrifuged for 1 minute at 1,000 RPM. An Oshion 800-1 centrifuge was used to conduct these experiments. After centrifugation, the samples were manually divided into three layers (Fig. 1) to check for density separation.

In the table above, calcium bentonite is more evident in the middle layer of the 2:1 sample while quartz and gypsum are both more noticeable in the bottom layer. There is little separation in the 1:2 ratio sample. The 2:1 sample is currently being submitted for composition analysis.

H.M. Holloway

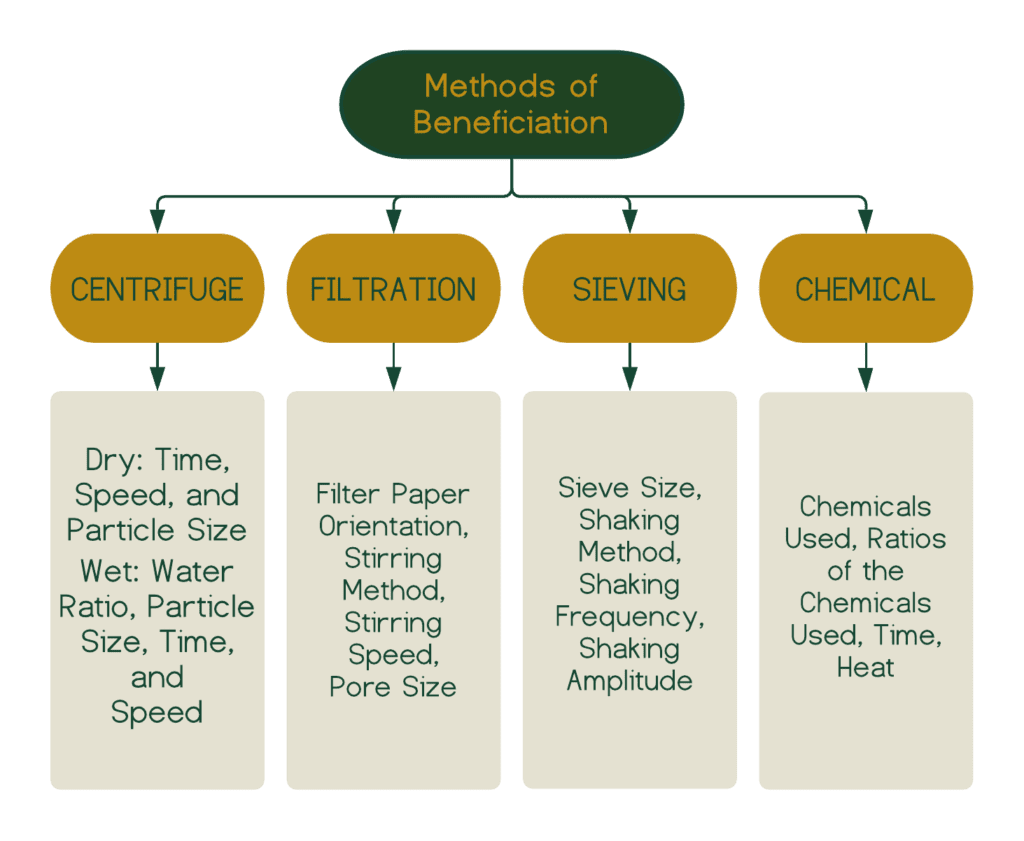

Methodology

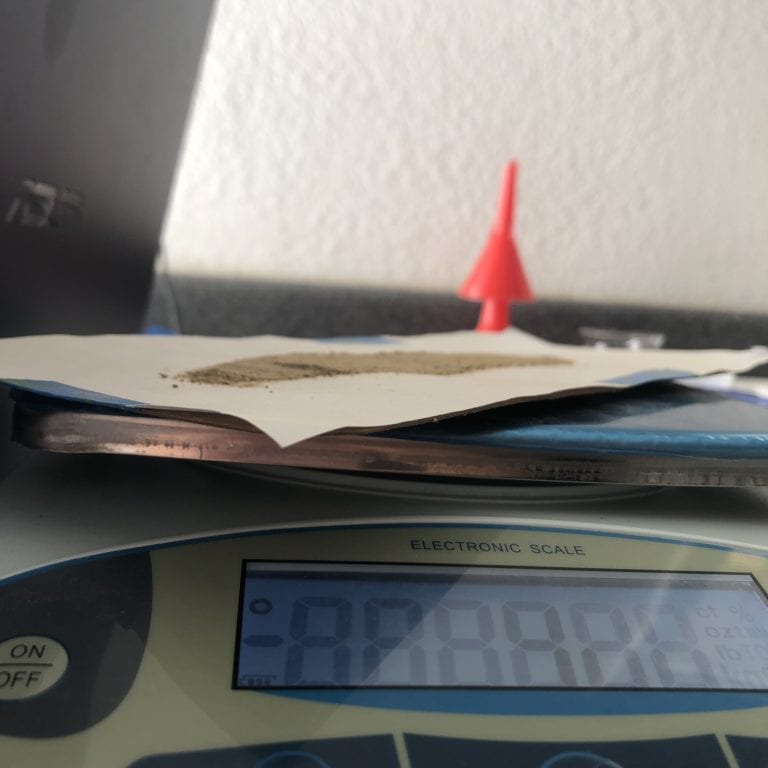

Filtering and Sieving

- The method of beneficiation that H.M. Holloway currently uses is most similar to a sieving process. This process is used because it does not require electricity or water to run.

- Sieving is used to separate particles by size. The calcium bentonite clay in the raw gypsum ore has a particle size of ~1-5 µm, whereas the gypsum and quartz have a particle size of ~1-2 mm. Therefore, the calcium bentonite clay can be separated through sieving.

- Sieving is cost-effective; however it is not the most effective beneficiation process as some impurities remain after sieving.

- Filtration is another method that can separate the calcium bentonite clay from the other two constituents. Filter papers with pore sizes of ~5-10 µm, ~10-15 µm, and ~20-25 µm were used. The pore size did not seem to affect the separation of the calcium bentonite clay from the other constituents.

- A range of water-to-ore mass ratios between 2:1 and 28:1 were tested for the filtration method. The minimum water-to-ore ratio that produced sufficient beneficiation was 6:1. The filtration method was successful but because of the large water requirement and time to separate the constituents, it is likely H.M. Holloway will not prefer this beneficiation method in the future.

Chemical

In this method, “Chemical X” refers to a proprietary chemical that is mixed with the raw gypsum ore to induce beneficiation. Mixing Chemical X with the raw gypsum ore does not generate any harmful byproducts that could negatively affect soil health. Some of the variables that were studied for the chemical beneficiation method were: the water amount used, particle size, Chemical X amount used, Chemical X to raw gypsum ore ratio, minimum time required for sufficient beneficiation, and heat.

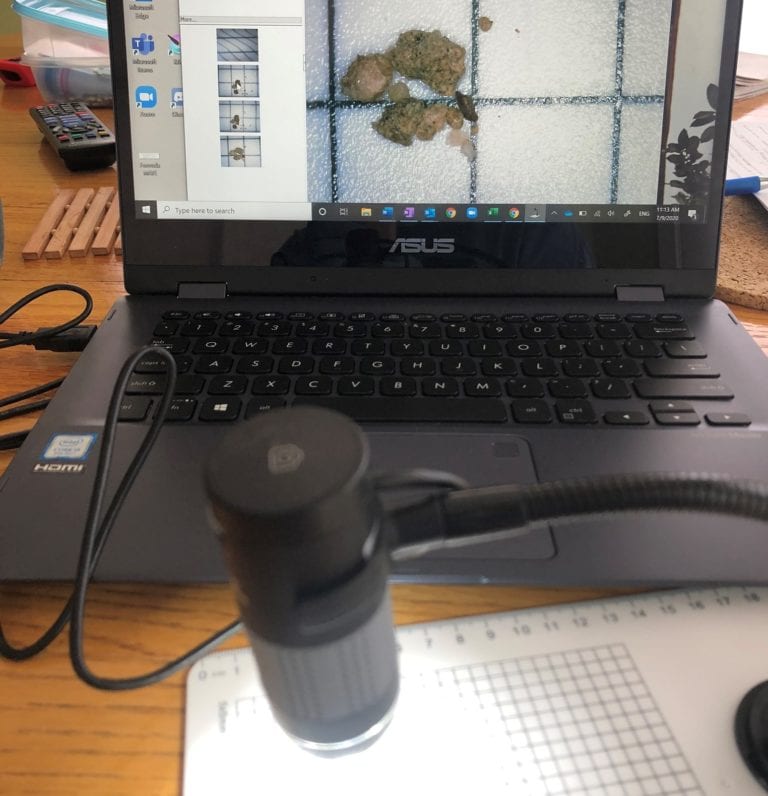

Unsurprisingly, smaller particles led to more significant beneficiation as they have greater surface area that can engage in chemical reactions. This experiment also determined optimal reactant amounts and reaction time to produce visual beneficiation. The chemical beneficiation method appeared to be successful in separating gypsum from the other main constituents in the raw gypsum ore. Figure 3 shows before and after pictures of a sample that underwent the chemical beneficiation process. Chemically beneficiated samples are currently being submitted for composition analysis.

Conclusion

GALLERY