Our Team

Tiffany Foo

Tiffany Foo is majoring in materials engineering with a minor in industrial technology. She aspires to work in the biomedical, automotive, or aerospace industry where she could apply her skills to develop new materials while also performing testing and failure analysis.

Rachel Potratz

Rachel Potratz is a materials engineering major. She aspires to work in the aerospace, automotive, or defense industry developing, testing, and performing failure analysis with new materials.

Acknowledgements

A special thank you to Dr. Kivy for guiding us through the learning curve on computational modeling and simulations. Additionally, thank you to the College Engineering for providing us the resources needed to make this project happen.

Tailoring Atomic Positions in High Entropy Alloys

Background

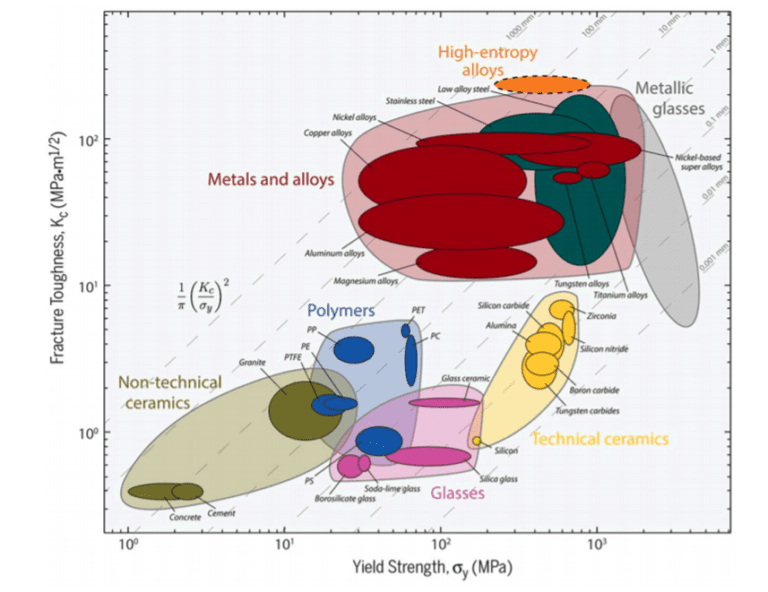

High Entropy Alloys (HEA) are also known as Multi Principle Elements (MPE) and Complex Concentrated Alloys (CCA). For the purposes of this research we focused on the HEA definition which concentrates on the configuration of molar entropy.

The development of HEAs began with the discovery in the 1990s as an undergraduate research project. Since then, starting in 2004, there has now been over 2,300 publications on the topic.

HEAs are important because they have great mechanical, electrical, thermal, and magnetic properties that can be used for applications such as thin film nitride coatings as diffusion barriers, hydrogen storage, and shape memory alloys which can be used in many industries.

Objective

To see if the atomic positions of the elements have an effect on the cohesive energy of selected High Entropy Alloys.

Method

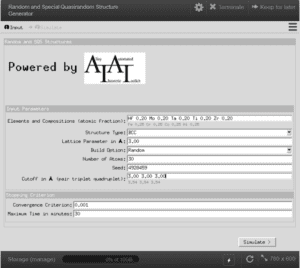

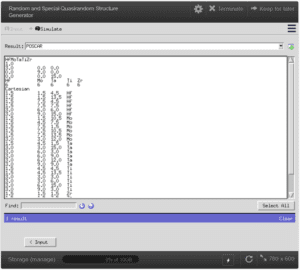

Step One

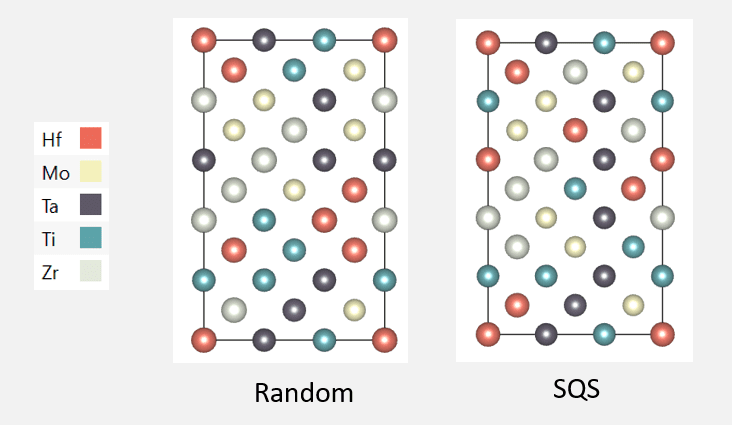

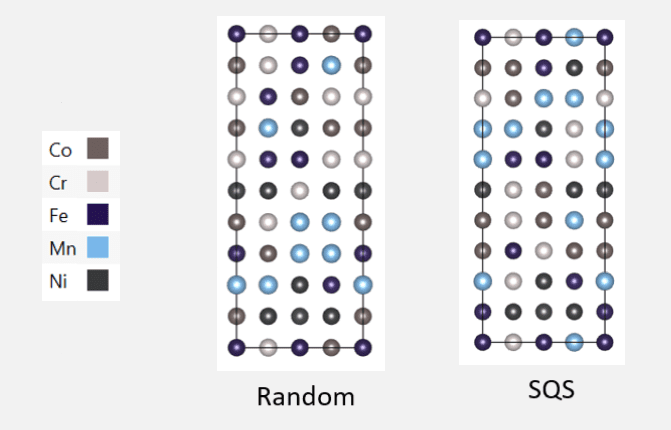

To investigate the effects of atomic positions on crystal structure energies we first used NanoHUB, a tool developed by students in materials engineering at Cal Poly and Purdue. Using this, we found the atomic positions of the chosen HEAs with both random and special quasi – random (SQS) algorithms (both are means of randomly assigning different positions). Below, is a screenshot of the NanoHUB input and output.

Method

Step Two

With the output from NanoHUB, we then used a software called Vesta to create 3D crystal structures for the selected alloys. Looking at the crystal structures, we ensured that all of atomic positions were filled. Below are one of the BCC and FCC selected alloys in the Vesta software.

BCC

FCC

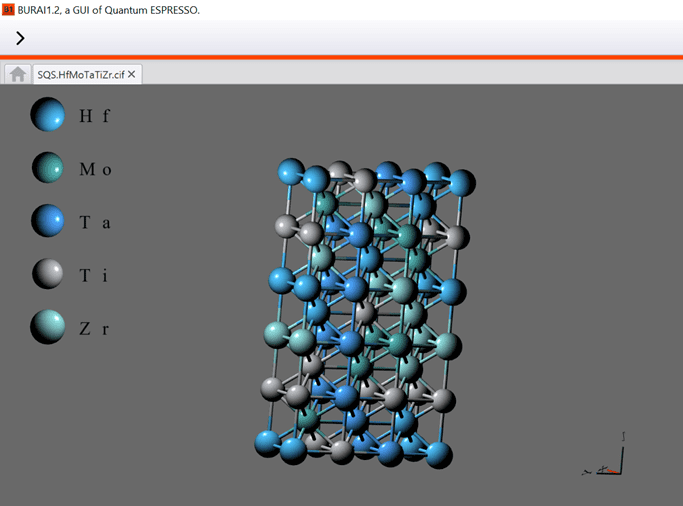

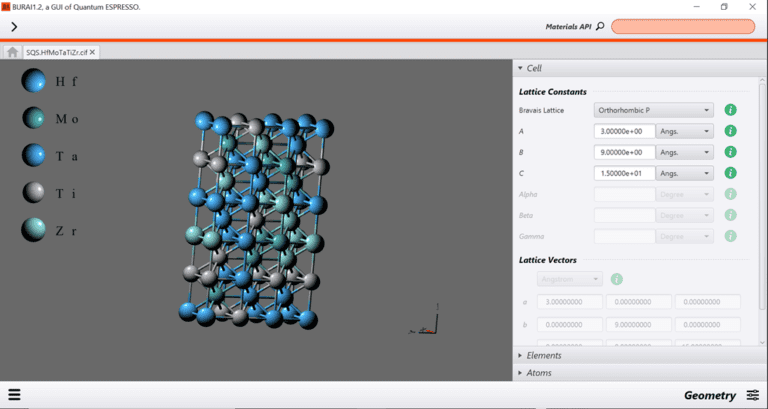

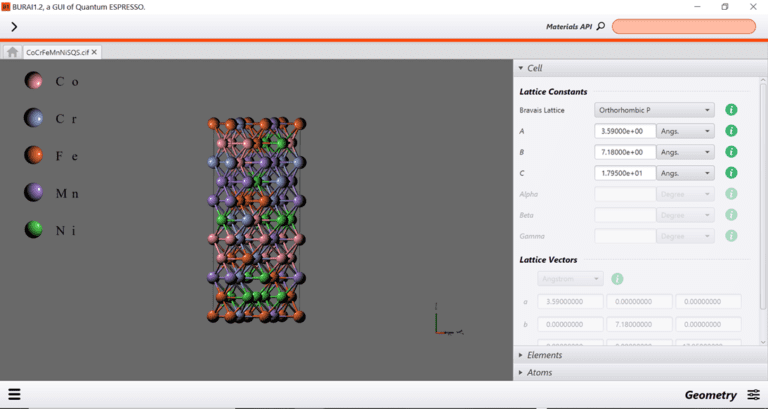

Step Three

We then converted the POSCAR file from Vesta into a cif file so that it could be read by the Burai software, a GUI of Quantum Espresso (a quantum-mechanics based software). Again, we ensured that the super cells looked intact and ran the program to find the cohesive energy of the cell. This would take approximately two – 24 hours depending on the alloy. Below is a picture of a BCC and FCC alloy in Burai.

Results

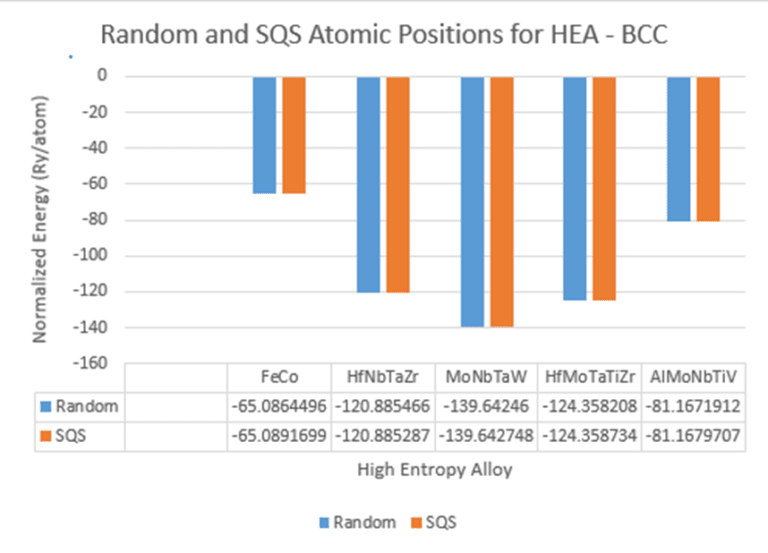

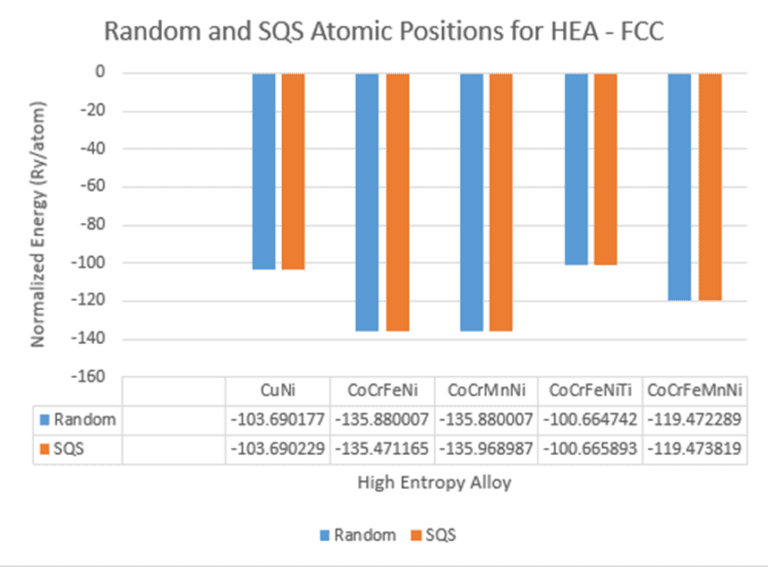

Given the Burai output of the cohesive energy, we calculated the normalized energy (Ry/atom). This allows us to make a comparison, as the super cells had different numbers of atoms. Below is a graphical representation of these values in each alloy comparing Random and SQS side by side.

The lack of any major difference between the normalized energies among random and SQS shows that there is no effect due to atomic positions.

Future

Our research on High Entropy Alloys this summer just scratches the surface. Next, we will investigate the effect of elemental distributions on vacancy and interstitial sites. The elements that will be interstitially added will be carbon and oxygen.

References

Esfandiarpour, A, and Nasrabadi, M.N. “Vacancy Formation Energy in CuNiCo Equimolar Alloy and CuNiCoFe High Entropy Alloy: Ab Initio Based Study.” Calphad, vol. 66, 2019, p. 101634.

Kivy, Mohsen & Hong, Yu & Asle Zaeem, Mohsen. (2019). A Review of Multi-Scale Computational Modeling Tools for Predicting Structures and Properties of Multi-Principal Element Alloys. Metals. 9. 254. 10.3390/met9020254.

Miracle, D.B, and Senkov, O.N. “A Critical Review of High Entropy Alloys and Related Concepts.” Acta 2019, nanohub.org/resources/sqsatat/aboutMaterialia, vol. 122, 2017, pp. 448–511.

Tripathi, Shivam, et al. “Random and Special Quasirandom Structure Generator.” NanoHUB.org, NCN, 30 Sept. 2019.