Our Team

The members of this project put forth effort, passion, and dedication to uncovering innovations in the field of construction, and are highlighted below:

Robert Sprotte

Student researcher

Robert is a 4th year Civil Engineering student concentrating in Construction. He spent this past summer working on this SURP project and as a field engineer intern on a construction site and hopes to begin a career in construction after graduation.

Andrea Leal

Student Researcher

Andrea is a 4th year Civil Engineering student with an interest in Construction and Project Management.

Hani Alzraiee

advisor

Hani is an Assistant Professor in the Department of Civil and Environmental Engineering as well as Co-Director of the Granite Heavy Civil Minor.

Acknowledgements

We would like to extend our thanks to the SURP Program, Cal Poly College of Engineering, and Cal Poly Department of Civil and Environmental Engineering for providing us with this opportunity to research an innovative field in the construction industry.

Project Summary and Reflection

Drone Applications in Construction

Abstract

In this project, we identified an opportunity to explore the incorporation of Unmanned Aerial Vehicles (UAVs) in the construction industry. In this investigation, we identified various applications for UAVs in construction and selected two potential drone uses that can improve worker safety and optimize construction work as our focus. Our analysis was twofold: using drones to identify and classify pavement marking defects with machine learning techniques and optimizing the concrete delivery path through UAV data and simulation modeling.

Pavement Marking

Defect Identification

Literature and Limitations

Road agencies rely on traditional methods for inspection. These are highly subjective and expose workers to the hazards of traffic. The goal of this section is to create a framework for using drones to capture data aided by machine learning to create an automated pavement marking defect identifier tool. This research was limited to using Google Satellite Images to simulate data collected by a drone.

Methodology

The four steps in the methodology are (1) data collection, (2) image analysis and multi-level classification, (3) R-CNN model development, and (4) model testing.

Machine Learning

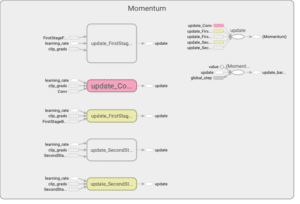

A Python-based, R-CNN model was developed using Google’s Tensorflow package for object detection. This model was modified from the original settings of a pretrained model. The layers were modified so the model could be tailored to detecting pavement marking data. The predefined model weights are also adjusted and optimized specifically for the pavement marking images Three iterations were made, each with increased data from satellite, Google images, to optimize the model to correctly detect pavement marking defects. The model was trained to detect 8 classes of pavement marking defects.

Results

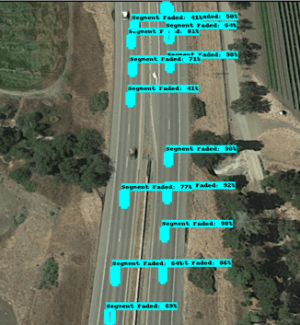

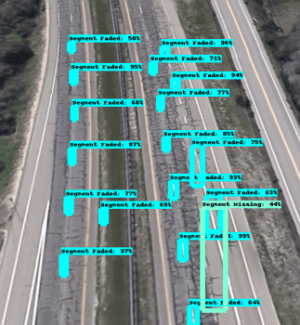

The last iteration of the model was given 540 training images and 60 test images. It was run for 46194 epochs for 16 hours. The model processed original shots of road segments (see Fig.1 and Fig. 2) and output images with predictions on feature detection (see Fig. 3 and Fig. 4). The results yielded 50 to 80 percent confidence levels in feature detection. The mean average precision (mAP) of the small, medium, and large features were 0.033, 0.064, and 0.025, respectively. More data, better model configurations, and increased training time will help increase these values and ultimately help model performance.

Optimizing Concrete Delivery

Literature and Limitations

Procuring, delivering, and pouring concrete is a major milestone in many construction projects. Planning is especially important for the ready-mix concrete (RMC) industry as it has more potential transport barriers than any other manufacturing industry since RMC has a low value-to-weight ratio and concrete discharge should occur within 90 minutes after mixing per ASTM C94. Simulation modelling has been investigated as a means for optimizing scheduling of various construction-related activities but these studies share a limitation in that they do not account for the impacts smaller scale factors, mainly pedestrians and bicyclists, can have on deliveries to populated areas and many do not explicitly use data collected by drones, which could prove a beneficial addition.

Methodology

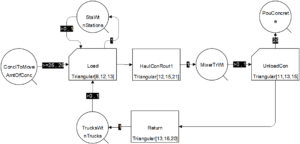

The proposed Automated Construction Data Acquisition and Simulation (ACDAS) framework is comprised of three main steps: collection, simulation, and reporting. Traffic data of a construction site in San Luis Obispo, California was collected, and EZStrobe discrete event simulation modelling was used to model three potential routes from a local concrete batch plant to the specified job site.

Discrete Event Simulation Model

EZStrobe takes multi-step activities, such as concrete delivery, and models them as just one activity and provides a duration that represents the time it takes to perform all n steps. The model is run for each of the route alternatives and the results are analyzed and summarized to highlight the most efficient concrete delivery route.

Results

The simulation model results determined that routes S01 and S03 (R1 and R3) are very similar with total operation times of 5.9 and 5.95 hours, respectively while S02 (R2) yields a duration of 3.1 hours. Based on the model output, R2 should be chosen over R1 or R3 for the concrete delivery in this specific task. These results highlight the impact route selection can have on the overall duration of a large concrete pour activity.

Table 1: Preliminary Results of the Simulation Model

Conclusion

Our team determined that:

- Drones provide a safer alternative to traditional methods of road inspection.

- Expansion of this work could lead to a predictive model in GIS that monitors the service life of pavement markings in real time.

- Drones can be used to collect traffic data to feed into a simulation model to predict the optimal travel times for a concrete delivery.

- Future work can utilize drone data collected from a busy college campus to determine if small-scale factors such as pedestrians and bicycles will significantly affect travel times.

Other Uses for UAVs in Construction

The applications of UAVs in constructions are not limited to the two topics we researched. Drone usage in construction is constantly expanding and there are many other areas to investigate. Some examples for future research are listed below.

Structural Assessment of Bridges

Site Layout Optimization in Preconstruction

Enhancing Construction Worker Safety on Roads

References

Xu, S., J. Wang, P. Wu, W. Shou, T. Fang, and X. Wang. Vision-Based Pavement Marking Detection – A Case Study. 2020.

Zang, J., W. Zhou, G. Zhang, and Z. Duan. Traffic Lane Detection Using Fully Convolutional Neural Network. 2019.

Zhang, D., X. Xu, H. Lin, R. Gui, M. Cao, and L. He. Automatic Road-Marking Detection and Measurement from Laser-Scanning 3D Profile Data. Automation in Construction, 2019. https://doi.org/10.1016/j.autcon.2019.102957.

Ersoz, A., and O. Pekcan. Unmanned Aerial Vehicle Based Pavement Crack Identification Method Integrated with Geographic Information Systems. 2017.

Chen, P. R., S. Y. Lo, H. M. Hang, S. W. Chan, and J. J. Lin. Efficient Road Lane Marking Detection with Deep Learning. 2019.

Lu, H.C. Lam, Optimized concrete delivery scheduling using combined simulation and genetic algorithms, in: Proc. – Winter Simul. Conf., 2005. https://doi.org/10.1109/WSC.2005.1574553.